RUBYCON: Three new Developments for E-Caps

RUBYCON responds to Market Needs

DC charging stations and OBCs have high ripple current requirements for DC link capacitors. RUBYCON responds to market needs by introducing three new developments that result in a reduction of the sizes used and a lower number of capacitors.

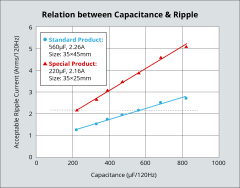

1) Increase in Ripple Current With Minimum Increase in Capacitance:

There is a correlation between capacitance and ripple current for capacitors. If they are only selected based on the required ripple current, the capacitance value of the DC link capacitor could be higher than necessary. This leads to a higher price of the components, as these factors are directly proportional to each other. RUBYCON's new technology enables a higher ratio of ripple current to capacitance. Through adapted capacitor structure, electrolytes, separator paper and other factors, the electrolytic capacitor can be precisely adapted to all customer requirements.

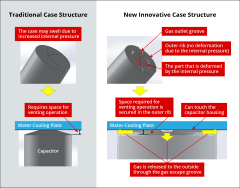

2) Innovative Capacitor Housing Structure for Water Cooling:

Until now, electrolytic capacitors have been difficult to cool because they require some space at the top due to the safety vent, which prevents direct contact with a water cooling plate RUBYCON has developed a new housing design that allows the capacitor to touch the heat sink without losing the space required for safety venting. Due to the forced cooling, the condenser temperature can be kept lower and a higher ripple current utilisation is achieved compared to normal conditions.

3) New Technology for Further Miniaturisation:

Even though some of the existing series are much smaller than those of the competitors, RUBYCON is developing a new technology that allows the component size to be reduced by up to 15%. Once this technology is further refined, even more size reductions are possible.

These three developments make it possible to reduce costs. In addition, smaller dimensions and lower weight in OBCs will undoubtedly also contribute to better energy efficiency.

Your Contact Person

For more information, please contact Yasunobu Ikuno.