SUMIDA's PANTA Increases Added Value

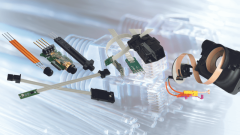

SUMIDA PANTA© Flexible Modules

For customers in the automotive and industrial sectors, SUMIDA flexible connection is mainly known as a leading manufacturer of flexible flat conductors and printed circuit board connectors (so-called jumpers). With the Flexible Modules product group, SUMIDA bridges the gap between its core portfolio of flat conductor production and the connection and integration of other components and functions.

Advantages and Process Know How:

With the Flexible Modules, this opens up the possibility of obtaining greater added value from a single source and thus reducing the number of suppliers, among other things.

Advantages:

- In-house assembly of printed circuit boards

- Assembly of more complex components

- Extensive portfolio in the area of process technology, e.g. lasers, various welding and soldering processes, etc.

Process Know How:

- Lamination:

In the lamination process, copper conductors are laminated between the top and bottom with pressure and temperature. The foils are coated on one side with an adhesive system. The copper conductors lie parallel to each other; combinations of different pitches are possible. - Cutting systems:

The laminated mother reels are separated by slitting processes and cut to the final width. Subsequent cross-cutting produces the required length of the cables. - Stripping:

The production of the terminal ends of the cables is carried out by the process of stripping. In this process, the insulation is stripped from the copper with special knives. If required, the conductor ends can be further processed according to terminal shapes by the respective bending tools. - Crimp-technology:

Terminating crimp contacts for flat conductors with 1.27mm and 2.54mm pitch. - Overmolding:

Fully hydraulic sliding table injection molding machines overmold the cable ends and flexible modules. - Moulding with hotmelt:

Hotmelt is characterised by clean processing properties, naturally without solvents or other harmful substances. Wherever good adhesion to conductive and housing materials and low processing pressure are required, hotmelt is particularly suitable. With low pressure, the molten, low-viscosity hotmelt is injected into the cavities, gently flushing around even filigree components, thus sealing and protecting them. - Bonding:

Special equipment puts adhesive tapes and reinforcements on the FFC cables and ZIF jumpers. - Laser processing:

High-precision, high-performance laser quickly and very flexibly realises customer-specific variants of uncovering. - Soldering:

Selective soldering systems guarantee optimum soldering with the lowest possible heat load on the components. Placers and a reflow soldering system are available for soldering SMD components. - Resistance Welding:

The contacting of components and PANTA® cables by means of resistance welding guarantees a safe and very high-quality interface. - Folding:

Customised designs possible through robotic folding - Assembly:

The selection of the optimal assembly line is based on the technical and qualitative evaluation of the customer-specific module, taking into account the cost-benefit principle.

FMS - Flexible assembly systems guarantee a high-quality module even for medium quantities.

AMS - Automatic assembly systems produce customer-specific modules in large quantities fully automatically.

We are happy to support you in the design of a new Flexible Module.

Your Contact Person

For more information, please contact Julia Reiterer.